Select Filling Technology According to Material Characteristics

Different materials require corresponding filling systems:

Powders are best measured with auger (screw) fillers; granules can be handled with multi-head or linear weighers; liquids use piston pumps or electromagnetic pumps for precise dosing.

From fine powders to high-viscosity liquids, Auger Enterprise provides stable and efficient equipment solutions.

-

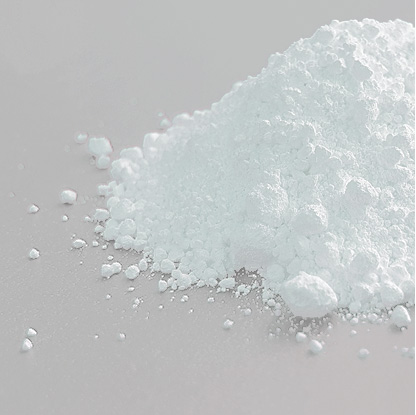

Powder Filling Packaging Solutions

In manufacturing across various industries, most raw materials, semi-finished products, and finished products exist in powder form. Due to differences in powder particle size, texture, flowability, and uniformity, selecting precise and stable metering and filling equipment is crucial.

-

Granule Filling Packaging Solutions

For various industries dealing with dry solid products such as granules, strips, flakes, and irregular shapes, selecting an effective, stable, and precise metering and packaging system is crucial. Auger Enterprise has extensive experience in designing packaging machines and solutions for dry solid products, catering to the packaging needs across various industries.

-

Liquid Filling Packaging Solutions

For liquid products with varying viscosities, flow characteristics, foam tendencies, and chemical properties, filling and packaging equipment requires high precision and stability. Choosing the right filling solution not only ensures consistent product quality but also improves production efficiency.

-

Customized Solutions

In the field of packaging machinery, we understand that no single solution can meet all needs. Every packaging project comes with its own unique challenges. With our extensive experience and technical expertise, we are willing to take on high-difficulty applications that other companies may avoid. Built upon the mature design of our standard equipment, we are passionate about tackling diverse challenges, providing innovative designs or professional advice, and delivering customized solutions tailored to your requirements.