TS-2435CF

Vertical Granule Packaging Machine

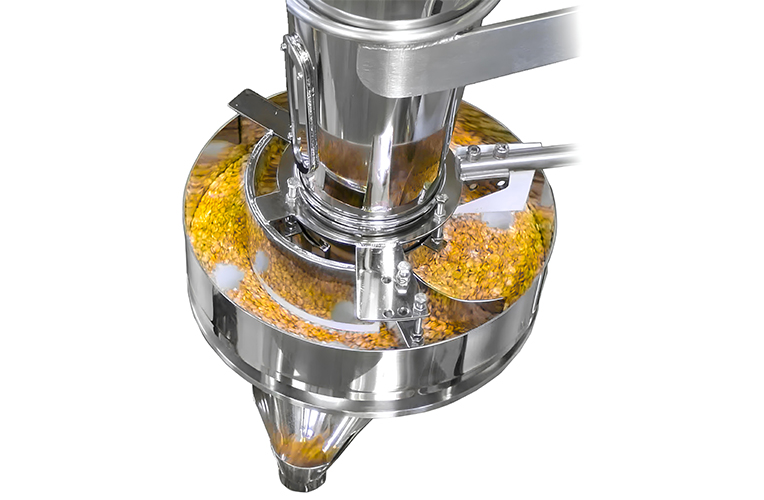

TS-1625 / 2435CF The TS-1625 / 2435CF is a machine that uses volumetric cup filling combined with a vertical form-fill-seal (VFFS) machine for producing large packaging products. It is widely used across various industries for products with relatively uniform shapes, such as salt, sugar, pet food, granular dry fertilizers, snack foods, and grains.