Linear Weigher with VFFS Machine

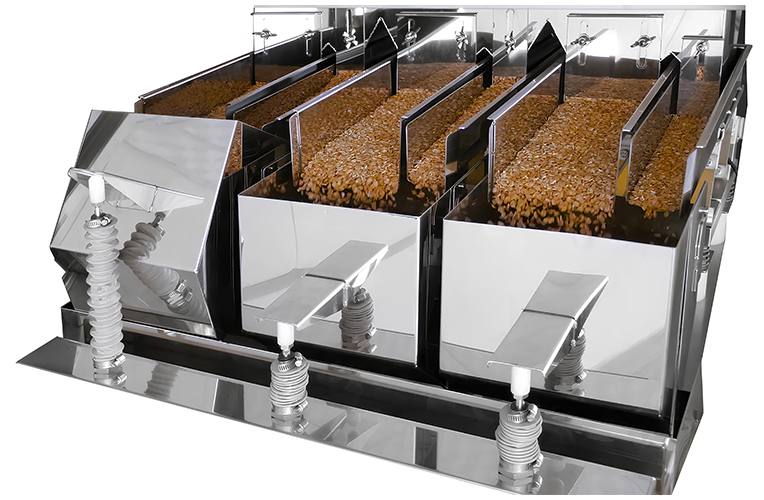

The TS-2435-VB is specifically designed for packaging coffee beans, utilizing linear scale metering combined with a vertical packaging machine. During bag formation, the degassing valve is automatically embedded in the package. It releases CO2 emitted by roasted coffee beans while preventing oxygen ingress. This valve keeps the coffee beans dry, maximizing freshness.