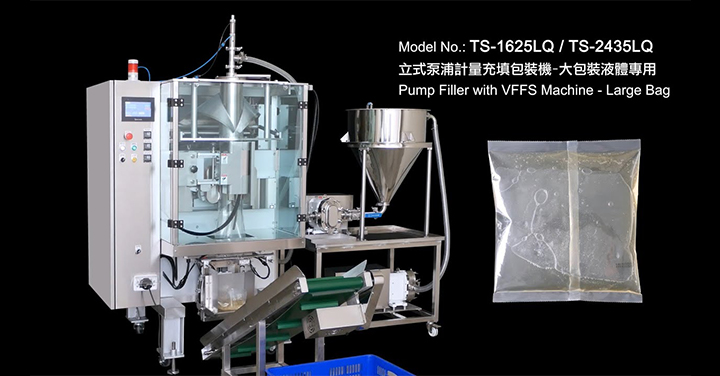

Filling features

Based on liquid products' characteristics and filling weight to choose the suitable pump system, such as piston pump, peristaltic tubing pump, or mono pump to achieve stable and accurate filling measurement.

Packaging features

- The packaging bag forming section utilizes a collar-type bag forming device and a palm-press sealing mechanism, to ensure that the packaging produced has a neat appearance, tight seals, and no trapped material or pinholes.

- The collar-type bag former is constructed from stainless steel corrugated plates and meticulously handcrafted with a specific arc ratio to ensure packaging symmetry during continuous production. It is also equipped with a quick-detach mechanism for ease of installation and disassembly by operators.

- The eye mark sensor is used to detect the eye marks on the packaging film, ensuring the precise cutting position. Regardless of the location of the eye mark on either side of the packaging material, adjustments can be easily made, and in cases where there are no eye marks on the packaging film, the cutting length can also be set through the HMI touch screen.

- The installation/replacement position for packaging film adopts a low-hanging design in line with ergonomics, making it more ergonomic, efficient, and safe to operate.

- Sealing temperature control adopts PID calculation, with temperature variance controlled within ±2°C, ensuring tight and stable packaging output.

- Through the synchronous operation and cooperation of the paper pulling system and the braking system, it leads to a minimum loss of packaging film and to a maximum accuracy of package forming.

Control features

High-quality control components, such as PLC, servo motors, and pneumatic cylinders sourced from Japan, Europe, and America, are utilized to ensure smooth and stable mechanical operation.

The touchscreen HMI can meet various operational requirements. It is equipped with 10 built-in production memory modules, and users can effortlessly switch between Chinese and English languages for enhanced convenience during setup and operation.

The machine features an automatic abnormality detection system. In the event of an abnormality, the machine will halt automatically, display the fault location on the screen, and activate a warning light to alert the operator for prompt attention.

This machine can be linked with other required equipment to complete an efficient production line.

Pack Style

-

Pillow Pack

-

Pillow Pack + Round Hole

-

Pillow Pack + Butterfly Hole

-

Gusseted Pouch

Specification

| Application | ||

|---|---|---|

| Model | TS-1625LQ | TS-2435LQ |

| Bag Dimensions | W: 80~160 mm L: 150~250 mm |

W: 160~240 mm L: 180~350 mm |

| Filling Weight | 100~1000g | 600g-2000g |

| Metering Accuracy | ±1~2% | |

| Packaging Speed | 12~25 bags/min | |

| Suitable Packaging Film Materials | Laminated PP, OPP, PET, Aluminum Foil and Nylon. | |

| Specification | ||

| Machine Dimensions | L: 1015 × W: 1450 × H: 2900 mm | L: 1190 × W: 1490 × H: 3050 mm |

| Machine Weight | 600kg | 750kg |

| Machine Construction | Machine structure is made of stainless steel SUS304 and aluminum alloy. Material contact parts are made of stainless steel (Standard 304 / Optional 316). | |

| Metering Method | Based on product characteristics to choose the metering pump: piston pump, peristaltic tubing pump, or mono pump. | |

| Control Features |

|

|

| Power Required | 220V, 3Ø, 7.5HP, 50/60Hz (Customizable) | |

| Air Pressure | 5~6 kg/cm2 | |

| Standard Components | 100 Liters hopper (single layer), Liquid filling device (based on product characteristics), Bag former, Hot stamp date coder, Finished product conveyor. | |

| Optional Equipment | Double layer heating hopper, Liquid filling device (based on product characteristics), Bag former, TTO / Inkjet printer, Liquid supply pump, or other required equipment/accessories. | |

*The above related specification content can be adjusted according to product requirements or after actual testing. Please confirm with our sales representatives before purchasing.

*Packaging speed and accuracy are determined by the result of the actual material testing.