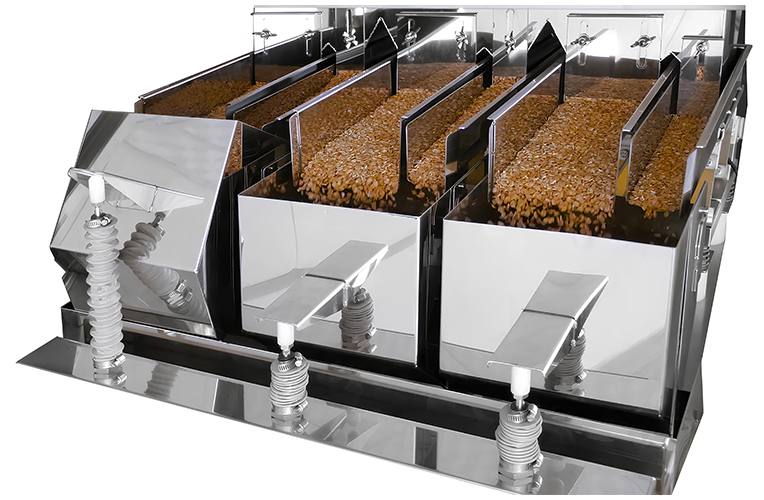

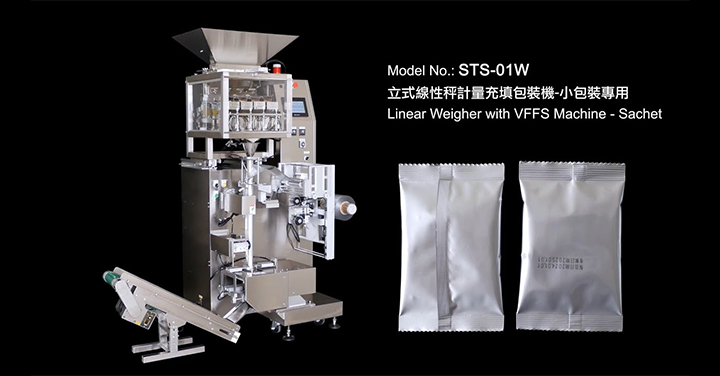

Linear Weigher with VFFS Machine

The STS-01W utilizes linear scale metering in combination with a vertical packaging machine to produce sachet products. It is extensively used across various industries for packaging products with relatively uniform shapes, such as sugar, pet food, granular dry fertilizers, snack foods, medicinal tablets, and grains.