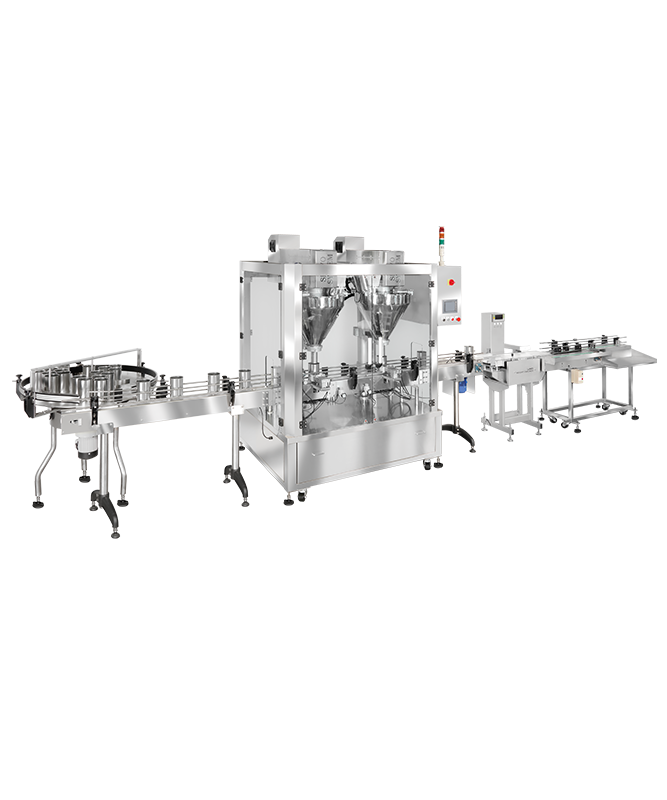

SM-2101-2H

Linear Auger Fillers

SM-2101-1H / SM-2101-2H is a filling machine designed for medium-volume powder dosing into bottles or jars. It can be integrated with an automatic production line including a feeding system, capping machine, and labeling machine. Widely used in various industries such as food, pharmaceuticals, health supplements, cosmetics, and chemicals.