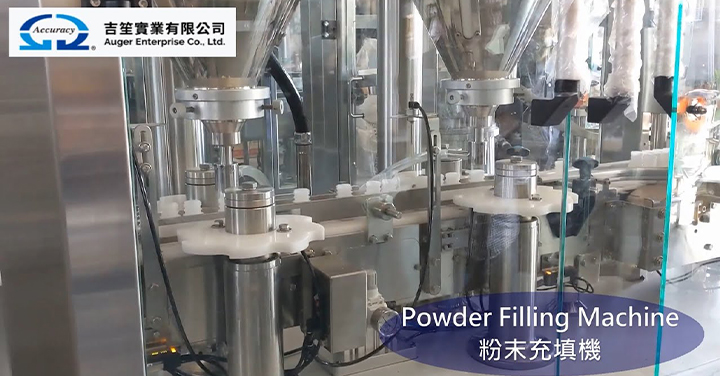

SM-2102-2H

Linear Auger Fillers

SM-2102-1H / SM-2102-2H is a filling machine specifically designed for dispensing small quantities of powder into bottles or containers. When integrated with an auger replenishment system, capping machine, and labeling machine, it forms an automated production line widely used across various industries such as food, pharmaceuticals, health supplements, cosmetics, and chemicals.