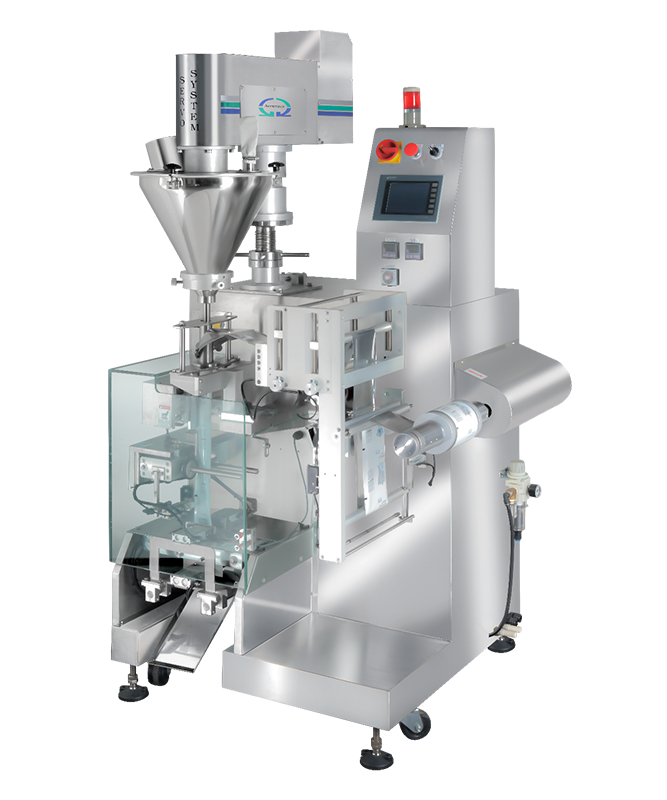

STS-01-L

Auger Filler with VFFS Machine

STS-01 Powder vertical form fill seal machine designed for producing sachet or stickpacks. It is suitable for a wide range of powders, including cocoa powder, coffee powder, tea powder, milk powder, grain powder, spice seasoning powder, chemical powders, and medicine powders.