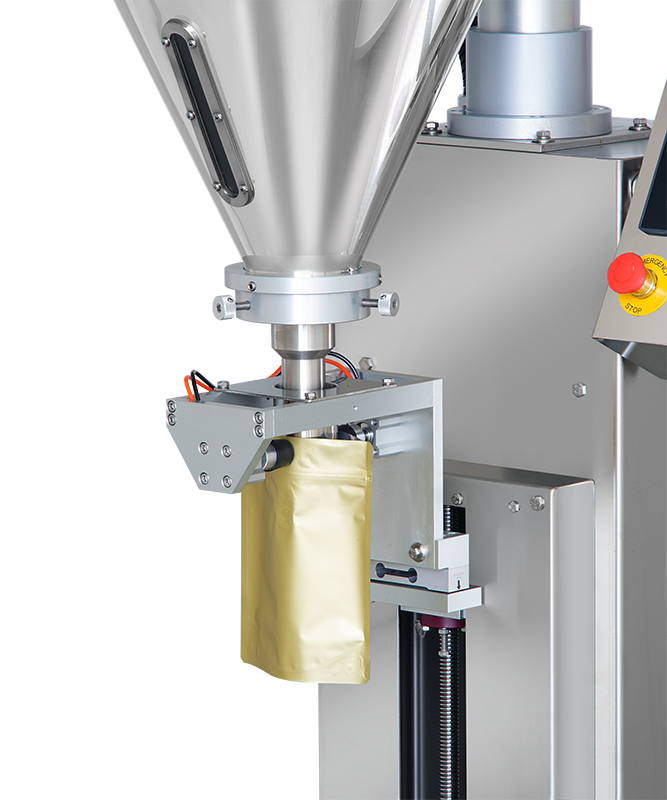

Semi-Automatic Auger Filler

SM-01 is Ideal for filling small-volume powder, applications in industries such as food, cosmetics, and pharmaceuticals. Capable of metering powders as small as 1g, it ensures both efficiency and accuracy while accommodating various types of containers. Additionally, it can be connected with other equipment to further enhance production efficiency.