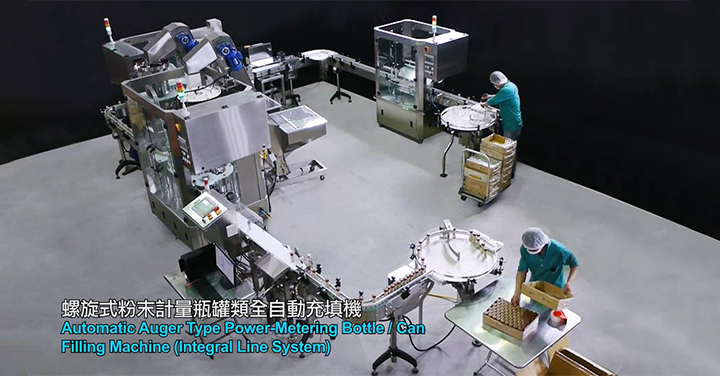

SM-2102-2R24

High Speed Rotary Auger Fillers

SM-2102-1R16 / SM-2102-2R24 is a high-capacity filling machine specifically designed for accurately dosing small amounts of powder into bottles and jars at high speed in continuous operation. When integrated with auxiliary equipment such as a feeding system, capping machine, and labeling machine, it forms a fully automated production line. Widely applied in the food, pharmaceutical, nutraceutical, cosmetic, and chemical industries.